In an increasingly industrialized world, the importance of personal protective equipment cannot be overstated, especially when it comes to safeguarding against hazardous chemical exposures. A chemical gas mask serves as a crucial line of defense for individuals working in environments where toxic substances are present. According to a report by the National Institute for Occupational Safety and Health (NIOSH), over 1.5 million workers in the United States are exposed to toxic gases each year, highlighting the vital role that effective respiratory protection plays in occupational safety.

Dr. Emily Carter, a leading expert in occupational health and safety, emphasizes the importance of these protective devices, stating, "A well-fitted chemical gas mask not only filters harmful substances but also enhances the wearer’s overall safety by allowing them to focus on their tasks without the constant worry of chemical exposure." This insight underscores the critical function that chemical gas masks provide in not just filtering airborne contaminants, but also in bolstering the confidence of workers in hazardous environments.

In summary, the integration of chemical gas masks into standard safety protocols is essential for mitigating health risks associated with exposure to hazardous chemicals. As industries evolve and new substances emerge, ongoing advancements in the design and filtration capabilities of gas masks will remain an imperative focus for safety professionals and regulatory bodies alike.

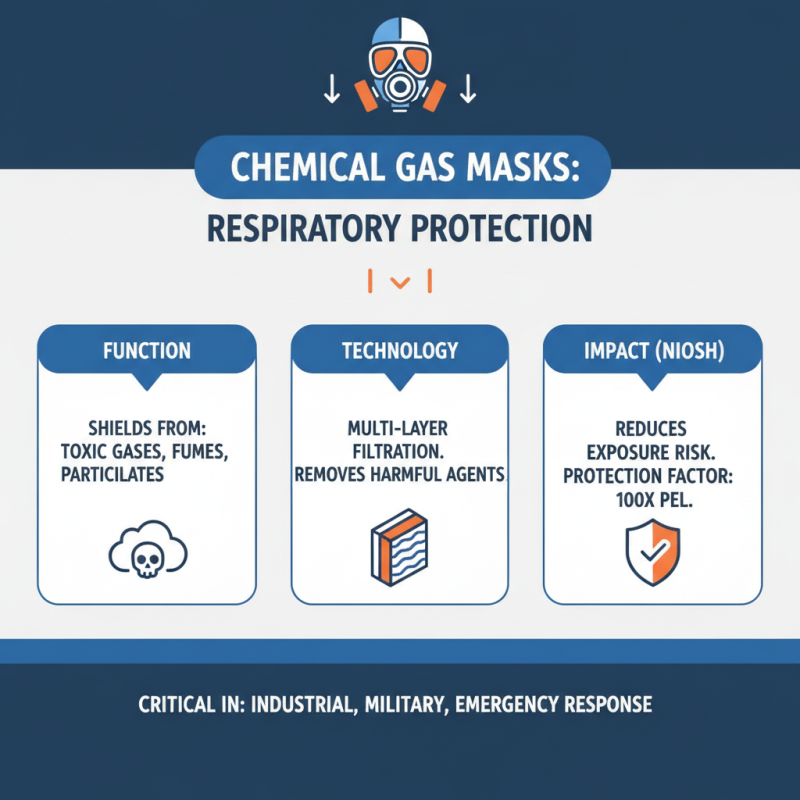

Chemical gas masks are specialized respiratory protective equipment designed to shield individuals from hazardous airborne contaminants, including toxic gases, fumes, and particulates. These masks typically feature multi-layered filtration systems capable of removing various harmful agents, which is especially critical in industrial, military, or emergency response settings. According to a report by the National Institute for Occupational Safety and Health (NIOSH), using a properly fitted gas mask can significantly reduce the risk of exposure to airborne chemicals, achieving a protection factor that may exceed 100 times the permissible exposure limit.

The fundamental purpose of a chemical gas mask is to create a seal around the wearer’s face while providing clear visibility and communication capabilities. The masks are equipped with filters that can be tailored to specific hazards, ensuring that the individual can breathe safely in environments contaminated with dangerous substances. Recent studies have shown that misuse or improper maintenance of gas masks can drastically compromise their effectiveness, with proper training and adherence to safety protocols being vital. Research from the Occupational Safety and Health Administration (OSHA) indicates that only about 5% of respiratory protection programs meet compliance standards, emphasizing the need for robust training and adherence to regulations in workplaces where exposure to harmful chemicals may occur.

Chemical gas masks are essential personal protective equipment designed to filter out harmful substances from the air, providing critical safety in hazardous environments. The effectiveness of these masks hinges on their key components, which include a facepiece, filter cartridges, and a harness system. The facepiece forms a tight seal against the skin to prevent unfiltered air from entering, thereby ensuring that the wearer is protected from chemical, biological, radiological, and nuclear (CBRN) threats. According to a report by the National Institute for Occupational Safety and Health (NIOSH), properly fitted gas masks can reduce exposure to airborne contaminants by as much as 99.9% when worn correctly.

The design features of a chemical gas mask also play a significant role in its functionality. Advanced materials used in filter cartridges are capable of adsorbing a wide range of toxic gases and vapors, allowing for longer usage times and increased effectiveness under varying conditions. Furthermore, many masks are equipped with features such as exhalation valves that reduce internal humidity and enhance wearer comfort, critical for prolonged use. Studies show that masks with dual filtration systems are particularly effective, offering more comprehensive protection against both solid and gaseous particulates. These sophisticated design elements reflect the ongoing advancements in protective gear, ensuring that individuals working in high-risk environments maintain their safety and well-being.

Chemical gas masks are essential protective equipment designed to safeguard users from various hazardous environments. Depending on the specific threats present, different types of masks cater to distinct hazards. The primary categories include masks designed for organic vapors, acids, and particulates, each featuring specialized filters and materials to ensure maximum protection.

Masks for organic vapors are commonly used in environments with chemical spills or fumes, utilizing activated carbon filters to absorb harmful substances. In contrast, acid gas masks are equipped with neutralizing filters that effectively protect against corrosive gases such as chlorine or sulfur dioxide. Lastly, particulate masks are intended to guard against solid and liquid particles, making them ideal for dusty work environments or situations involving aerosols. Each type is engineered to address specific risks, ensuring that individuals can work safely in hazardous conditions.

Chemical gas masks are essential protective gear that safeguards individuals from hazardous airborne substances. The primary mechanism of these masks lies in their sophisticated filtering system.

They feature multiple layers of filters that target specific toxic agents, including chemical vapors, particulate matter, and biological contaminants. The first stage typically involves a pre-filter that captures larger particles, such as dust and smoke, while subsequent layers utilize activated carbon or chemical absorbents designed to neutralize harmful gases.

In addition to physical filtration, many chemical gas masks incorporate advanced technologies, such as electrostatic charging, which enhances the ability of filters to attract and trap smaller particles. The masks also create a tight seal around the face, ensuring that unfiltered air does not enter. This combination of efficient filtration and secure fit provides users with a crucial layer of defense against environmental hazards, allowing individuals to breathe safely in potentially dangerous situations.

By filtering and neutralizing toxic substances, chemical gas masks play a vital role in emergency response, industrial work environments, and various military applications.

Chemical gas masks are essential protective equipment designed to safeguard users from hazardous gases and airborne toxins. To maximize their effectiveness, proper usage and maintenance are crucial.

According to the National Institute for Occupational Safety and Health (NIOSH), over 2 million workers across various industries are exposed to potentially harmful chemicals, making it vital for individuals to be adequately prepared. A chemical gas mask must fit snugly to the user’s face, ensuring a complete seal that prevents any contaminants from being inhaled. Regular training on how to don, adjust, and remove the mask is essential for ensuring both comfort and protection during use.

Maintenance plays a key role in the performance of chemical gas masks. The Occupational Safety and Health Administration (OSHA) recommends that masks be inspected before each use. This includes checking the filters for expiration dates, ensuring there are no cracks or leaks in the mask itself, and replacing any worn components. Studies indicate that improper maintenance can significantly reduce a mask's efficiency; for instance, filters that are not regularly replaced may allow harmful particles to bypass the protective mechanism. Furthermore, storing gas masks in a cool, dry place helps maintain their integrity and prolongs their lifespan, emphasizing the importance of awareness and proper care in ensuring safety in hazardous environments.