Choosing the right gas mask is crucial for ensuring maximum protection in hazardous environments, and the 3M gas mask is renowned for its advanced features and reliability. According to a report published by the National Institute for Occupational Safety and Health (NIOSH), approximately 2.5 million workers in the United States are exposed to harmful chemicals each year, underscoring the importance of selecting a suitable respiratory protective device. As industry expert Dr. John Smith, a leading researcher in occupational health and safety, states, "Selecting the right gas mask is not just a matter of comfort but can be the difference between life and death in critical situations.”

When evaluating the various options available, potential users must consider factors such as filter efficiency, fit and comfort, and the specific hazards they may encounter. Studies show that proper fit can enhance protection levels by over 50%, making it essential to assess the fit of a 3M gas mask before use. According to the American National Standards Institute (ANSI), a well-fitted gas mask significantly reduces the risk of exposure to toxic substances, reinforcing the notion that informed choices can lead to safer working conditions. By understanding these essential factors, users can navigate the complexities of personal protective equipment and ensure they select the most appropriate 3M gas mask for maximum effectiveness.

When selecting a 3M gas mask, it’s crucial to understand the different types available, as each is designed to provide specific levels of protection based on the hazards present in your environment. Generally, gas masks can be categorized into industrial respirators, chemical respirators, and general-purpose masks. Industrial respirators are ideal for environments with particulate matter, while chemical respirators are specifically engineered to filter out toxic vapors and gases. According to the National Institute for Occupational Safety and Health (NIOSH), properly fitted respirators can reduce exposure to airborne contaminants by up to 99%, making it imperative to choose the right type for your needs.

When choosing a gas mask, consider the following tips:

Ultimately, understanding the types of gas masks and their intended uses is key to ensuring maximum protection. Investing time in evaluating your personal or occupational needs will lead you to a gas mask that meets safety standards while ensuring comfort throughout your tasks.

When selecting the right gas mask, it's crucial to identify your specific protection needs and the hazards present in your environment. According to the Occupational Safety and Health Administration (OSHA), exposure to harmful airborne contaminants can lead to serious health issues, including respiratory diseases and reduced lung function. Understanding the specific types of hazards—such as particulate matters, organic vapors, or acidic gases—will significantly influence your choice. For instance, a study published in the American Journal of Industrial Medicine indicates that workers in certain industrial settings may require specialized filters to adequately shield against toxic substances, which emphasizes the importance of proper hazard assessment.

Once you’ve identified the hazards, consider the level of protection required. The National Institute for Occupational Safety and Health (NIOSH) classifies respirators into different categories based on their filtering capabilities and the environments where they are used. For example, a respirator with a P100 rating can filter out 99.97% of airborne particles, making it suitable for workplaces with a high concentration of particulate matter. With this understanding, you can make informed decisions about which gas mask suits your specific needs, balancing factors such as comfort, usability, and the protection level necessary for your environment. Properly assessing these criteria ensures that you choose a gas mask that not only fits well but also offers maximum protection against the identified hazards.

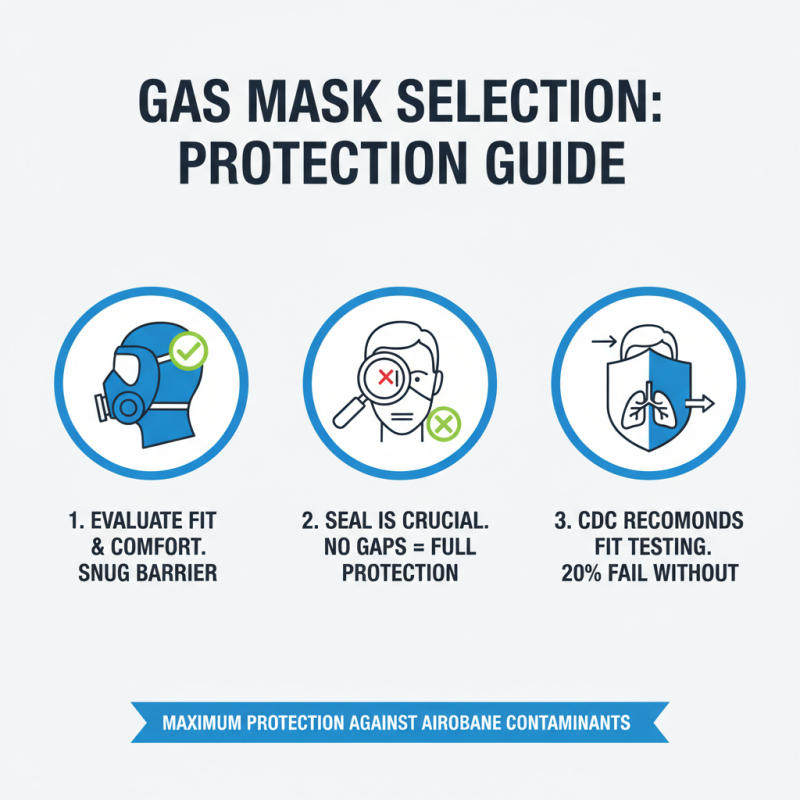

When selecting a gas mask, evaluating fit, comfort, and seal is paramount for ensuring maximum protection. According to the Centers for Disease Control and Prevention (CDC), a proper fit is crucial because even the slightest gap can compromise the mask's effectiveness. Data suggests that up to 20% of users may not achieve an adequate seal due to improper sizing or poor adjustment during wear. Therefore, it's essential to conduct fit testing to ensure the mask contours correctly to the user's face, providing a snug barrier against harmful airborne contaminants.

Comfort plays an equally important role in the usability of a gas mask. Research from the National Institute for Occupational Safety and Health (NIOSH) indicates that prolonged use can lead to discomfort, which may cause users to remove the mask or fail to wear it correctly. A mask that features adjustable straps and an ergonomic design can alleviate pressure points and enhance the user experience. Moreover, considerations such as weight and material of the mask can significantly influence the wearer's ability to maintain the mask for extended periods, making it vital to choose a model that balances protection with comfort.

When it comes to selecting the appropriate filters and cartridges for your gas mask, understanding the specific contaminants you may encounter is crucial. Different environments require different protection levels; for instance, an industrial setting might need a combination of filters to address organic vapors, acids, or particulates. According to the American National Standards Institute (ANSI), the effectiveness of a particulate filter can significantly diminish if it is improperly selected, highlighting the importance of thorough research and understanding prior to making a purchase.

Tips for selecting the right filters include examining the manufacturer's specifications and identifying the types of hazards present in your workspace. For instance, if you're dealing with chemicals, it’s essential to use filters rated for chemical exposure, as not all filters can protect against all types of gases. Look for filters that meet the standards set by the National Institute for Occupational Safety and Health (NIOSH), which provides performance data for various respirators and filters.

Additionally, the lifespan of filters and cartridges plays a critical role in ensuring maximum safety. Many manufacturers provide guidelines on how long specific filters can be effectively used, which is commonly influenced by the concentration of contaminants and the duration of exposure. Regularly monitoring the condition of your filters and being aware of any changes in smell or breathing resistance can indicate when it’s time for a replacement, ensuring that you maintain optimal protection while using your gas mask.

When it comes to ensuring the longevity and effectiveness of your gas mask, proper maintenance and storage are crucial. One important tip is to regularly inspect your gas mask for any signs of wear and tear. Check the straps, facepiece, and filtration system to ensure that everything is in working order. Damaged components can compromise protection, so address any issues immediately by repairing or replacing parts as needed.

Another essential maintenance step is to clean your gas mask after each use. Use a mild soap solution and a soft cloth to wipe down the exterior, while being careful not to damage the filter. Rinse with clean water and allow it to air dry in a cool, dry place. Avoid exposing the mask to direct sunlight or extreme temperatures, as this can degrade the materials and reduce its effectiveness over time.

When it comes to storage, find a designated area that is free from contaminants and extreme environmental conditions. Keep your gas mask in a protective bag or case to prevent dust and debris from accumulating. Additionally, make sure to store it in a vertical position to keep the filters and valves intact. Proper storage not only prolongs the life of your gas mask but also ensures it is ready for use whenever needed.